Hydro Cyclone

Filtration

Brightwater Hydro Cyclone Separator

HC centrifugal solid-liquid separator (VS separator for short) is designed for removing the precipitate solids from low viscous liquid. The HC separator’s removing efficiency depends on the particle density and the liquid viscosity. Higher solid density and lower liquid viscosity allow better separation performance. The removing efficiency is higher than 98% for iron particles larger than 40 micron in water. It can remove the particles down to 5 micron for higher density particulate iron. HC separator works without moving parts and needs no filter media change- out or cleaning. It requires little maintenance work. The consistent separation performance and economical running cost makes the HC separator ideal as a solidliquid separation filter system. A good configuration may be to filter liquid by the HC separator that is low cost with excellent reliable separating performance and then further filter the liquid by bag or cartridge filter. The integrated filtration system has higher filtering performance, no filter media consumption and no liquid discharge to waste.

Working Principal

HC separator uses the centrifugal force and the gravity sedimentation to separate the perceptible particles. After the liquid enters the tangential inlet (1), the slowing velocity increases by an internal acceleration ring (2). As the liquid spins through the separation chamber (3), the centrifugal force caused by the acceleration ring forces the perceptible particles to move onto the separation chamber (4) while the carrier liquid flows out of the outlet (5). The vortex breaker (6) allows the suspended particles to settle into the collection chamber (6). When the collection chamber collects enough particles, it is necessary to remove the solids out of the separator by an automatic time control purge valve (7).

Technical Features and Advantages

- Centrifugal solid-liquid separating, excellent separating performance

- No Filter media consumption, no filter media cleaning work

- Low pressure drop, steady flowrate and less pipeline energy consumption

- Good at removing high specific gravity particles from the low viscous liquid

- Working with no moving parts, almost no maintenance cost and high reliability

- Automatic purge option available, easy to adjust the best purging cycle

Typical Application

- Applicable industries: water treatment. Pulp and paper, petro-chemical, metal working

- Applicable liquids: source water (river water, seawater, underground water, sewage water, recycle water, coolant, cleaning agent)

- Main function: remove large particles, pre-treatment, purify the liquid, protect the key equipment Working type: hydro cyclone centrifugal separation, automatic online work

Brightwater Hydro Cyclone Separator

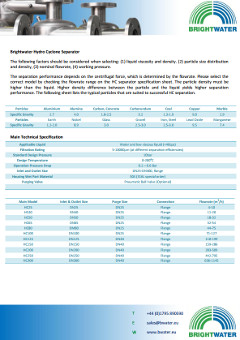

The following factors should be considered when selecting: (1) liquid viscosity and density. (2) particle size distribution and density, (3) nominal flowrate, (4) working pressure.

The separation performance depends on the centrifugal force, which is determined by the flowrate. Please select the correct model by checking the flowrate range on the HC separator specification sheet. The particle density must be higher than the liquid. Higher density difference between the particle and the liquid yields higher separation performance. The following sheet lists the typical particles that are suited to successful HC separation.